Predictive simulation, a key component of every smart manufacturing strategy, gives manufacturers insight into existing processes enabling future production and supply chain operations to be planned with unparalleled certainty.

INCREASE PRODUCTION

ELIMINATE BOTTLENECKS

REDUCE LEADTIMES

OPTIMISE SCHEDULES

Take Control of Your Smart Manufacturing Strategy

________

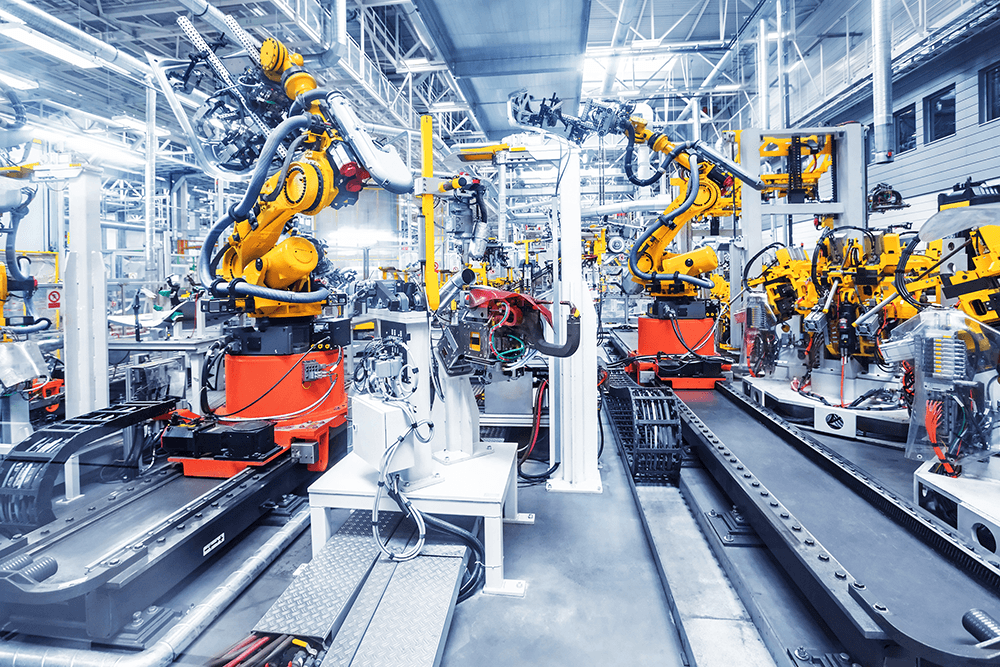

New technology and innovation is driving rapid change across the manufacturing sector. The digitisation and connectivity of manufacturing assets are creating the potential to meet customer needs with greater flexibility, faster time to market and reduced production costs. Unfortunately, investment requirements and payback periods lack clarity. These risks, disruptive competitors, and volatile markets are often prohibiting the evolution of manufacturing businesses.

Predictive simulation is an ideal starting point for manufacturers who wish to take advantage of modern IIoT/Industry4.0 technologies. By turning risks into clear opportunities, quantifying and controlling variability, highlighting and exploiting the projected value digitisation can bring to your businesses and accurately forecasting when an ROI on smart manufacturing technologies can be expected, simulation removes the barriers preventing change.

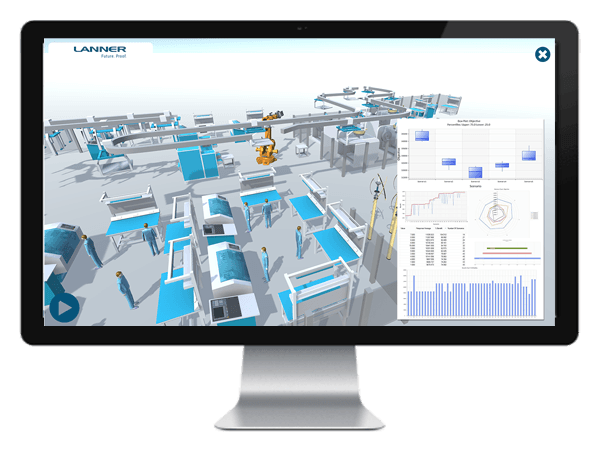

The Manufacturing Digital Twin

Take your management planning and continuous improvement initiatives to the next level with a predictive digital twin, a cyber-physical representation of your factory that gives life to your digitised devices and data.

Connect your models with live data streams straight from your production equipment, an MEP or IoT service layer to experience a visually rich representation of real world processes that can be played forward in time to understand future outcomes and performance.

These digital twins are unrivaled at engaging project stakeholders, effectively communicating how proposed process, technology and people changes will achieve your business goals.

- Increase production flexibility

- Reduce cycle times

- Improve quality and accuracy

- Improve production levels from existing capacity

- Secure investment and stakeholder commitments

- Get started with IIoT/Industry4.0

Production Planning & Scheduling

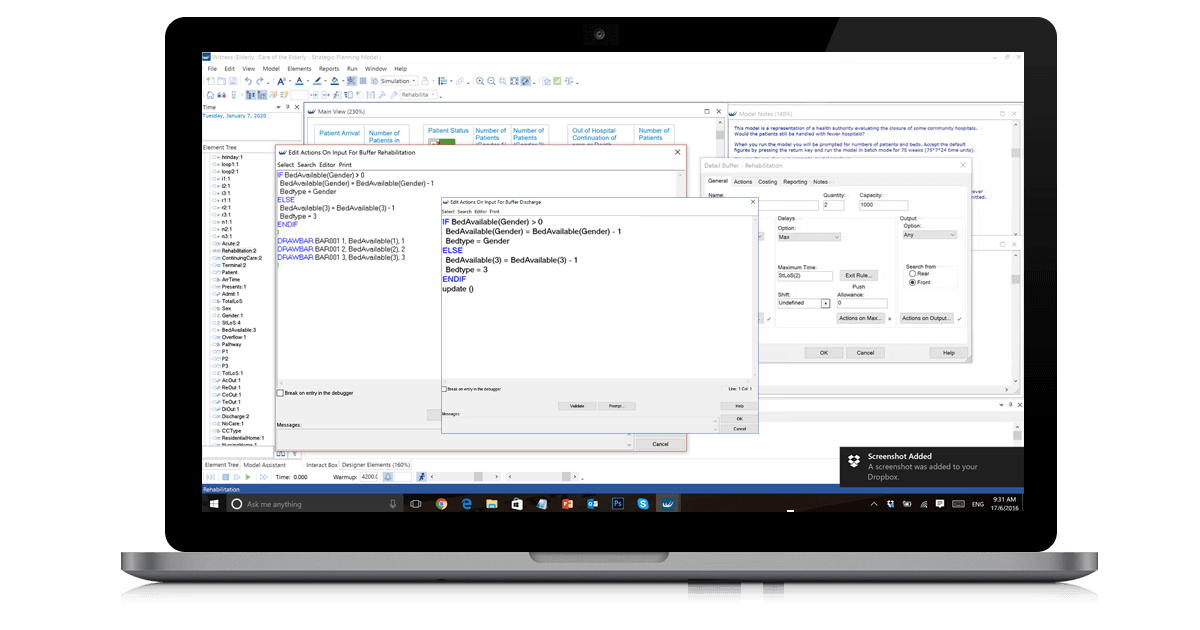

Predictive simulation models can be used to develop, test and optimise production schedules. By linking with live data systems, exceptions such as line faults, breakdowns, labor shortages, etc., can trigger predictive simulations to recalculate the new optimum process logic and reschedule production.

Continuous Improvement and Lean Manufacturing

A predictive simulation model acts as a sandbox for Lean and SixSigma initiatives to be designed, piloted, stress tested and optimised – all without disrupting current production. Avoid costly tactics that simply shift bottlenecks further down the production line and move continuous improvements strategies to a holistic business level.

Optimise Production

Predictive simulation technology allows companies to factor in ALL of the complex resource and process variables that manufacturing cells are subjected to when planning new equipment installations, layouts, workforce, sub-assembly processes, cranes, forklifts and more. Simulation allows for detailed analysis and experimentation to determine what business processes, resources and investments are required to achieve growth strategies and meet customer demand at appropriate costs.

New Product Introductions

Assess how new cells, lines and supply chain activities that are required to support new products will impact your current facility operations and production. A predictive simulation can help develop cost models, implementation plans, risk analysis and help get new products to market faster.